Stainless steel hollow sections play a crucial role in various industries, offering strength, durability, and versatility in structural applications. Whether it’s for construction, infrastructure, or architectural design, hollow sections are a preferred choice due to their exceptional properties and aesthetic appeal.

Understanding Stainless Steel Hollow Sections

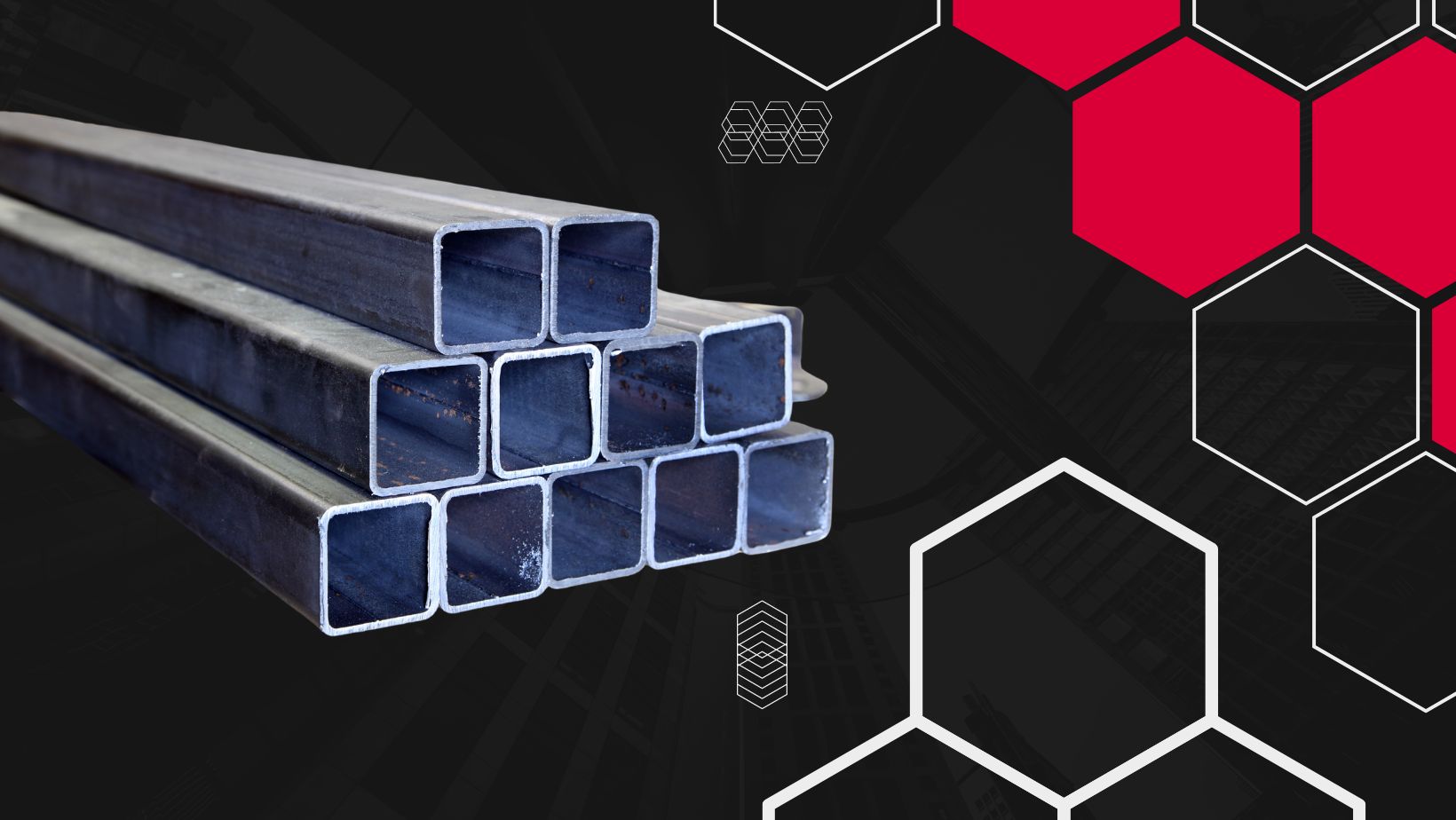

Steel hollow sections, also known as steel tubes or pipes, are hollow, cylindrical or square structures made from stainless steel. They come in various shapes and sizes, including rectangular, square, and circular, catering to different structural needs.

They are widely used in construction, infrastructure, automotive, and other industries due to their superior strength, corrosion resistance, and aesthetic appeal.

Types of Stainless Steel Hollow Sections

Hollow sections come in three main types:

- Rectangular hollow sections (RHS): have a rectangular cross-section and are commonly used in construction and architectural applications.

- Square hollow sections (SHS): have a square cross-section and are often used in infrastructure projects and decorative purposes.

- Circular hollow sections (CHS): have a circular cross-section and find applications in the oil and gas industry, handrails, and structural supports.

Properties of Stainless Steel Hollow Sections

Hollow sections exhibit remarkable properties that make them ideal for various applications:

- Strength and durability: Stainless steel is known for its high strength-to-weight ratio and durability, making hollow sections suitable for supporting heavy loads and withstanding harsh environmental conditions.

- Corrosion resistance: Stainless steel is highly resistant to corrosion, rust, and staining, ensuring long-term performance in outdoor and corrosive environments.

Manufacturing Process

Hollow sections are manufactured through various processes:

- Hot finished: This process involves heating the stainless steel billet or ingot to high temperatures and then passing it through a series of rollers to achieve the desired shape and dimensions.

- Cold formed: In this process, stainless steel strips or sheets are cold rolled to form hollow sections with precise dimensions and tolerances.

- Welded: Welded hollow sections are fabricated by joining steel plates or strips together using welding techniques such as arc welding or laser welding.

Applications

Hollow sections find widespread applications across different industries:

- Construction: Used for building frames, columns, beams, and other structural components in residential, commercial, and industrial buildings.

- Infrastructure: Utilized in bridges, tunnels, railings, and pedestrian walkways for their strength, durability, and corrosion resistance.

- Architectural design: Employed in modern architectural designs for their sleek appearance, versatility, and aesthetic appeal.

- Automotive: Used in automotive chassis, exhaust systems, roll cages, and other structural components for their lightweight yet robust properties.

Advantages

Hollow sections offer several advantages over other materials:

- Versatility: Available in various shapes, sizes, and grades to suit different applications and design requirements.

- Longevity: Resistant to corrosion, rust, and degradation, ensuring long-term performance and minimal maintenance.

- Sustainability: Made from recyclable materials and contributing to green building initiatives by reducing carbon footprint.

- Aesthetic appeal: Sleek, modern appearance enhances the visual appeal of structures and architectural designs.

Maintenance Tips

To maintain the performance and appearance of hollow sections, consider the following tips:

- Cleaning and upkeep: Regularly clean the surfaces using mild detergent and water to remove dirt, dust, and grime.

- Corrosion prevention: Apply protective coatings or inhibitors to minimize the risk of corrosion and extend their lifespan.

Future Trends

The hollow sections industry is witnessing several trends and innovations:

- Innovations in manufacturing: Advancements in fabrication techniques, such as additive manufacturing and automated production processes, are improving efficiency and reducing costs.

- Emerging applications: Hollow sections are finding new applications in emerging industries such as renewable energy, aerospace, and advanced manufacturing.

Conclusion

Stainless steel hollow sections are versatile, durable, and aesthetically pleasing structural components widely used in various industries. With their exceptional properties and applications, steel hollow sections are set to continue shaping the future of construction, infrastructure, and design.